The team behind LIFE EGGSHELLENCE shows that eggshells can be used to make ceramic wall tiles.

Each year, European egg processing companies generate around 150 000 tonnes of eggshell waste that is disposed of in landfill sites. This waste often causes odours and leads to the growth of harmful bio-organisms. For a medium-sized egg production company, the cost of transporting and disposing of the waste is between €50 000 and €200 000 per year.

The LIFE EGGSHELLENCE consortium is converting this waste into a valuable product used to manufacture wall tiles. The team also aims to minimise the extraction of virgin raw materials from nature.

They have already successfully installed a prototype on the premises of a project partner in Navarra, Spain.

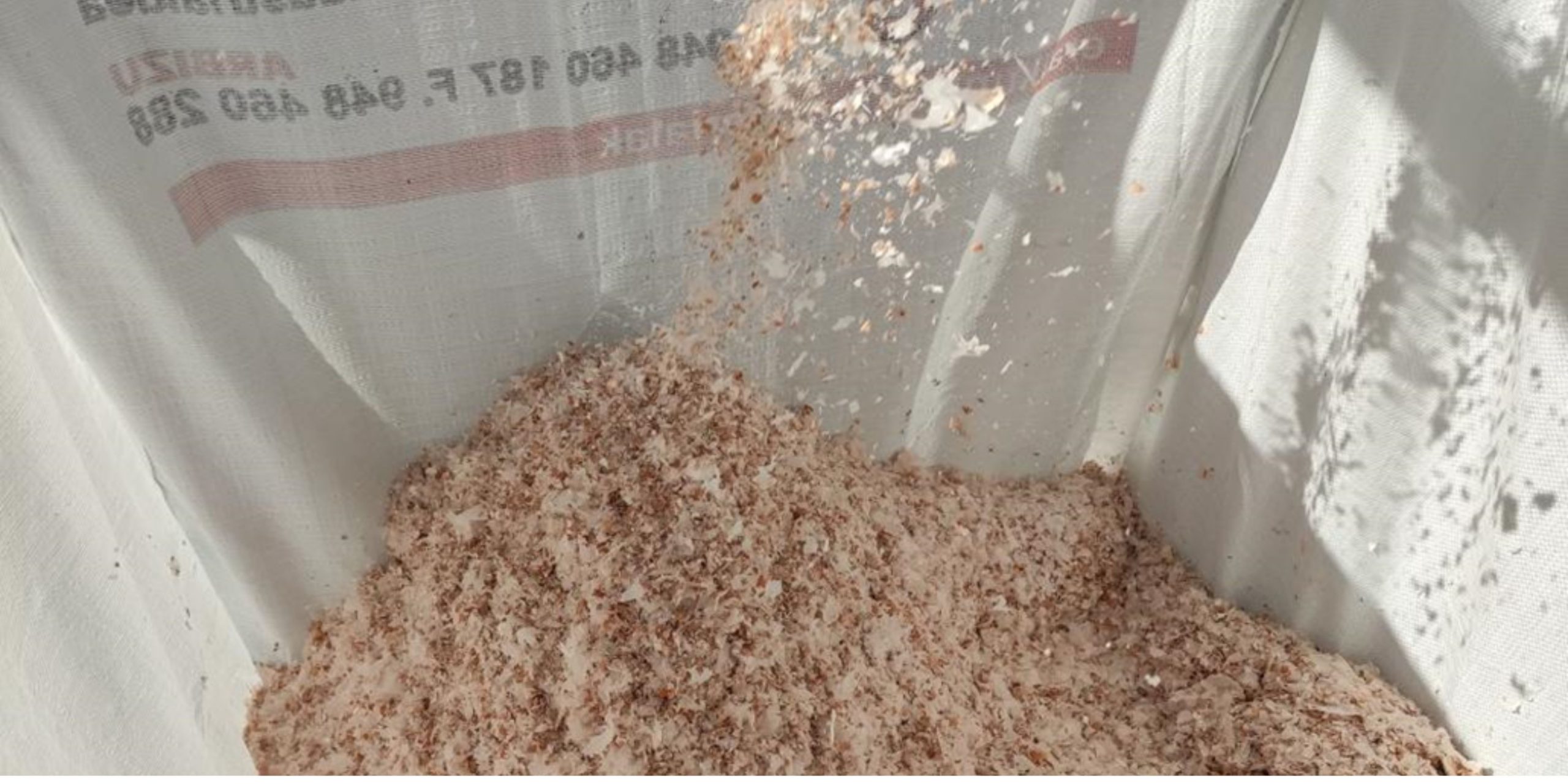

The prototype is operational and successfully separates the biological membrane from eggshell waste.

The resulting calcium bio-carbonate is used as a secondary raw material to replace mineral calcium carbonate in ceramic tile compositions.

Tests are now being carried out to achieve the maximum possible shell recovery.

The project team estimates a waste reduction of at least 70% per annum. They say 5 400 tonnes of eggshell will be recycled in Portugal and 5 600 tonnes in Spain yearly.

The calcium bio-carbonate extracted from eggshells would replace 18% of the raw material currently used to make ceramic tiles in Portugal – this equates to 30 000 tonnes per year. In Spain, it would replace 4% – an estimated 150 000 tonnes per year.

LIFE EGGSHELLENCE enables industrial symbiosis – the process by which waste or by‐products of an industry or industrial process become the raw materials for another.

The project will achieve a circular economy between two sectors, generating two new value chains and new business models that can be replicated elsewhere.

LIFE EGGSHELLENCE supports the EU’s new Circular Economy Action Plan, which is one of the key elements of the European Green Deal. The project also contributes to the EU’s Waste Framework Directive.

Source: European Commission I CINEA (https://bit.ly/3quu1KT)